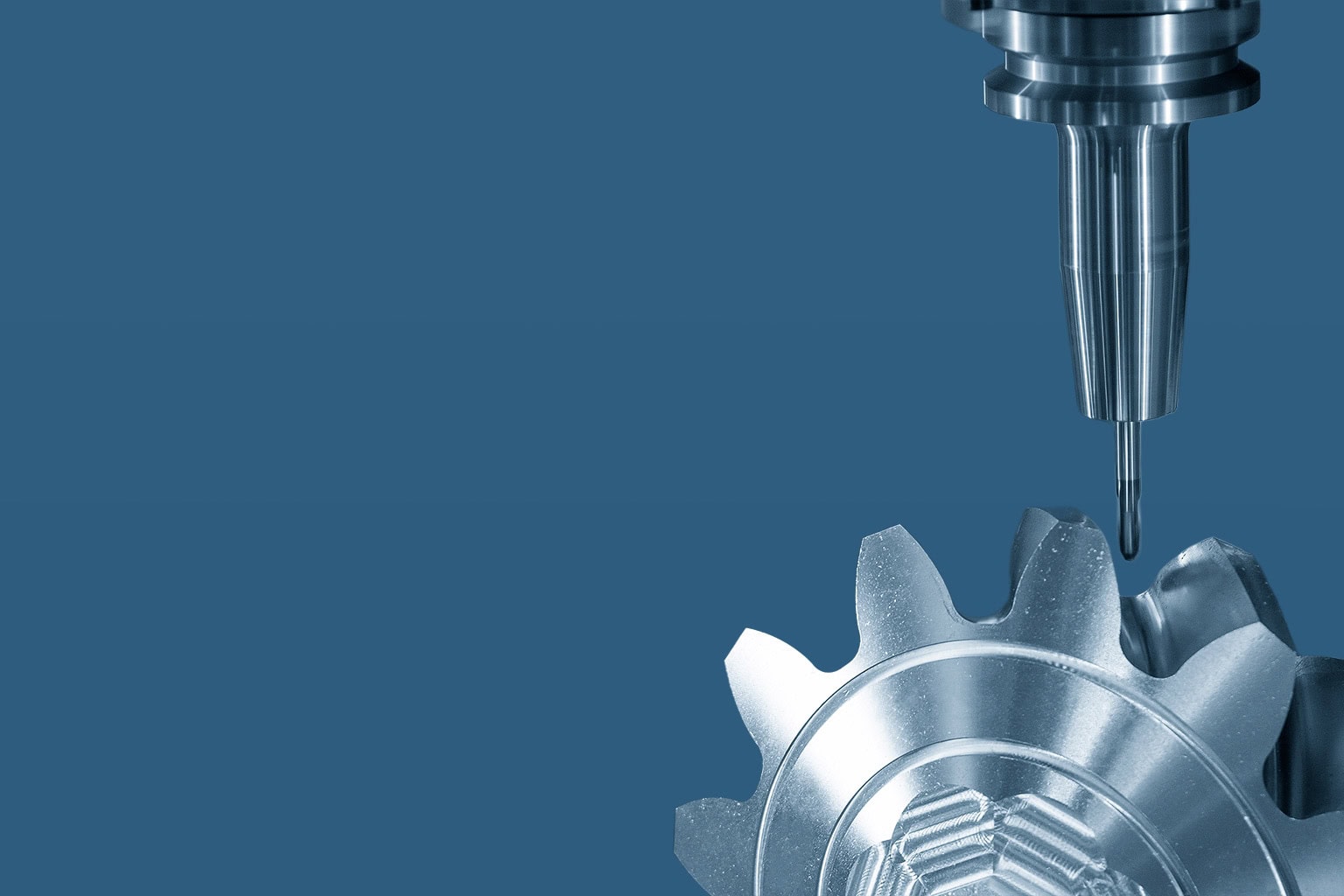

CNC precision machining that meets the highest standards

At ACI Industries, we specialize in CNC precision machining that meets the highest standards of performance, repeatability, and speed.

From our advanced facility in Mequon, Wisconsin, we support customers nationwide with expertly machined metal and plastic components—from concept to full production.

As a trusted Tier 1 supplier, we bring together tight-tolerance machining, responsive lead times, and deep engineering collaboration to help you meet specs, scale up production, and stay ahead of schedule.

ACCURACY

High-precision CNC machining